The Double Loop Wire Binding process typically requires several machines and tools to effectively bind documents. Here are some of the essential ones:

1.Wire Binding Machine:

A wire binding machine is the centerpiece of the process. It combines the punching and binding functions into a single unit. It typically includes adjustable features for punching hole patterns that match the chosen wire binding elements and paper size. Some advanced models might also have integrated wire closers.

2.Punching Unit:

If your wire binding machine doesn't have an integrated punch, a separate punching machine is needed. This machine allows you to punch holes in the paper to accommodate the wire binding elements. Punching units often come with guides and adjustable settings to align the holes properly and maintain consistent spacing.

3.Wire Closer:

After the pages are punched and the wire binding elements are inserted, the wire closer is used to secure the binding. This machine helps close the wire loops around the punched holes tightly, ensuring a firm and professional-looking bind.

4.Wire Cutting Tools:

Wire binding elements are often purchased in longer lengths and need to be trimmed to match the width of the document. Wire cutting tools, such as wire cutters or specialized cutting blades, are used to trim the excess wire length to ensure a clean finish.

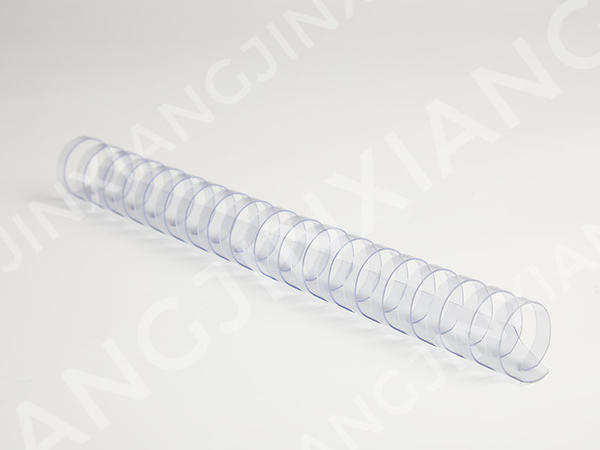

5.Wire Binding Elements:

These are the metal wires with double loops that hold the pages together. Wire binding elements are available in various diameters and colors, allowing you to choose the appropriate size and style for your document. They come in spools or pre-cut lengths.

6.Paper Jogger:

A paper jogger is used to align and square up the pages before punching holes. This helps ensure that the holes are accurately aligned and consistent throughout the document. It reduces the risk of pages shifting during the binding process.

7.Pliers or Closing Tools:

If your wire closer is not automatic, pliers or specialized closing tools might be needed. These tools allow you to manually close the wire loops around the punched holes, providing a secure bind.

8.Paper Trimmer/Cutter:

After the binding is complete, a paper trimmer or cutter can be used to trim the edges of the bound document. This step creates a neat and professional appearance, ensuring that no excess paper hangs beyond the wire binding.

9.Materials and Supplies:

You'll need an adequate supply of paper for the pages of your document, front and back covers (if desired), and wire binding elements. Depending on your project, you might also require specialized covers designed for wire binding.

10.Work Surface:

A sturdy and organized work surface is essential for the binding process. This space should provide enough room to accommodate your wire binding machine, tools, and supplies while allowing you to work comfortably.

11.Measuring Tools:

Measuring tools such as rulers or guides might be necessary to ensure accurate hole placement and wire length. These tools help maintain consistency across the document.

Double loop binding wire is a versatile and durable binding solution commonly used in the binding industry. It consists of two metal wires that are looped and bound in parallel to create a double loop pattern.

Double loop binding wire is available in various colors and sizes, making it suitable for a wide range of binding applications. It is commonly used for creating professional-looking document presentations, reports, calendars, notebooks, and more.

English

English 中文简体

中文简体 Español

Español