Achieving professional and flawless plastic spiral bound results requires attention to detail and following certain tips and tricks. Here are some useful tips to help you get the best results when using plastic spiral binding:

1.Properly prepare your documents: Ensure that your documents are printed or copied on standard-sized paper and that the pages are aligned and in the correct order before punching.

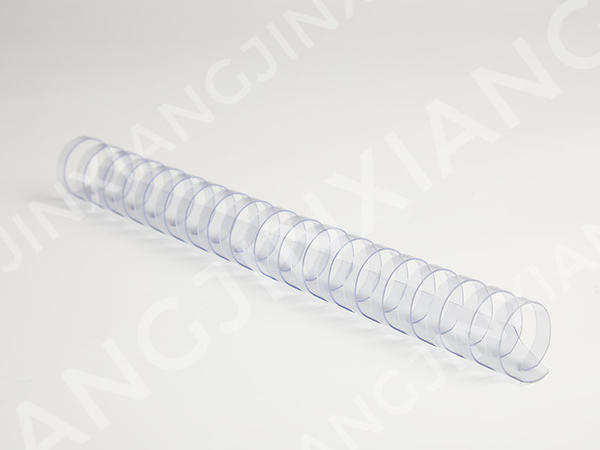

2.Choose the right plastic spiral binding supplies: Select the appropriate diameter of the plastic spiral coil based on the number of pages you are binding. The coil should extend slightly beyond the edge of the document to provide better protection.

3.Invest in a quality plastic spiral binding machine: Using a reliable and accurate plastic spiral binding machine is essential for achieving consistent and secure bindings. Choose a machine that aligns and punches the holes accurately.

4.Align the pages for punching: Make sure the pages are aligned properly when punching. Use guides or alignment markers on the binding machine to ensure consistency and prevent misalignment.

5.Punch consistently and cleanly: Apply even pressure when punching the holes to ensure clean and precise cuts. Avoid punching too close to the edge to maintain the integrity of the document.

6.Thread the plastic spiral coil carefully: Hold the plastic spiral coil by its end and gently thread it through the punched holes. Take care not to bend or kink the coil, as this can affect the overall appearance and functionality of the binding.

7.Use a coil inserter or crimping tool: Consider using a coil inserter or crimping tool to help insert the plastic spiral coil into the punched holes. These tools make the process easier and help ensure a tight and secure bind.

8.Trim and crimp the excess coil: After threading the plastic spiral coil through the holes, trim off any excess length using coil-cutting pliers or a coil cutter. Then, use a coil crimping tool to crimp the ends of the coil to prevent the pages from slipping out.

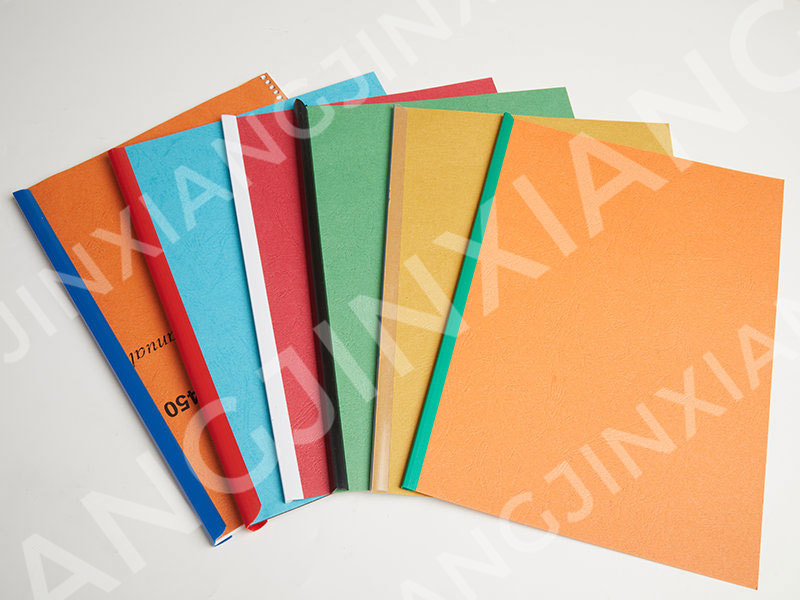

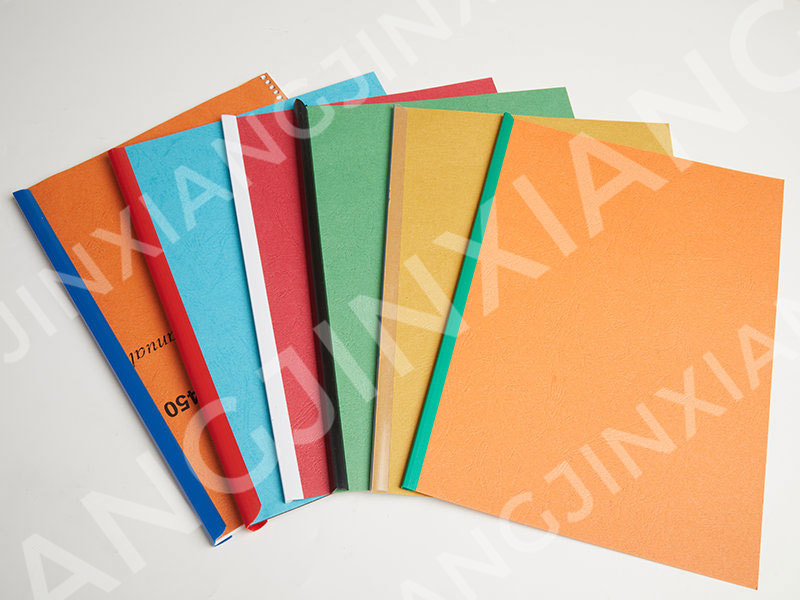

China Plastic Slide Binder manufacturers can achieve professional and visually appealing plastic spiral bound results. Paying attention to details, using high-quality supplies and equipment, and practicing the process will help you master the art of plastic spiral binding.

COLOR: Black/ White/ Clear/ Colorful.

SPEC: 4-16mm, usual 4mm/6mm/8mm/10mm/12mm, Triangle/ Round back.

SIZE: 297mm/310mm (others can be customized)

PACKING: White corrugated box/ Color box/ in bulk.

English

English 中文简体

中文简体 Español

Español