The versatility of a plastic binding comb system in handling various types of paper, including glossy or textured paper, depends on several factors. Here are some considerations:

Punching Capacity: Examine the plastic binding comb machine's technical specifications to ascertain its punching capacity, often expressed in terms of the number of sheets it can effectively punch at once. Higher punching capacities, such as those exceeding 20 sheets, indicate a robust machine capable of accommodating thicker or coated papers. This feature is paramount for users dealing with a variety of document thicknesses, ensuring efficiency and productivity in the binding process.

Adjustable Punching Depth: The adjustable punching depth feature is a sophisticated capability that allows users to customize the penetration of the punching mechanism based on the thickness and texture of the paper being used. This level of customization is invaluable when working with diverse paper materials, ensuring that the machine can delicately handle thinner papers while exerting more force for thicker, textured options. This adaptability contributes to achieving clean and precise punches without compromising the integrity of the paper.

Compatibility with Coated Paper: Investigate whether the plastic binding comb system explicitly mentions compatibility with coated or glossy paper. Coated papers often present challenges, such as increased slipperiness during the punching process. Systems designed to address these challenges typically incorporate features like enhanced friction control or specialized punching mechanisms to prevent misalignment. Such considerations are crucial for users frequently dealing with coated papers, ensuring a seamless and error-free binding experience.

Punching Pattern: Assess the diversity of punching patterns available on the plastic binding comb system. Different document types or sizes may require specific punching patterns to achieve optimal binding results. A system offering multiple punching options, such as comb, coil, or wire patterns, provides users with the flexibility to adapt the binding process to the unique requirements of each document. This versatility is particularly advantageous for users dealing with a variety of document formats and styles.

Special Features: Explore whether the plastic binding comb system incorporates advanced features specifically designed to address challenges associated with glossy or textured paper. Anti-jam technology, for example, can prevent frustrating interruptions during the punching process, while a reverse function enables users to rectify misfeeds or jams promptly. These specialized features contribute to a smoother and more efficient binding experience, particularly when dealing with papers that may pose unique challenges.

Sample Testing: If feasible, conduct comprehensive sample testing with the specific glossy or textured paper types intended for use. This hands-on approach involves systematically assessing the plastic binding comb system's performance across various parameters, including punching precision, alignment, and overall binding quality. By conducting thorough sample tests, users can validate the machine's capability to consistently deliver the desired results without compromising the integrity of the paper or the overall document.

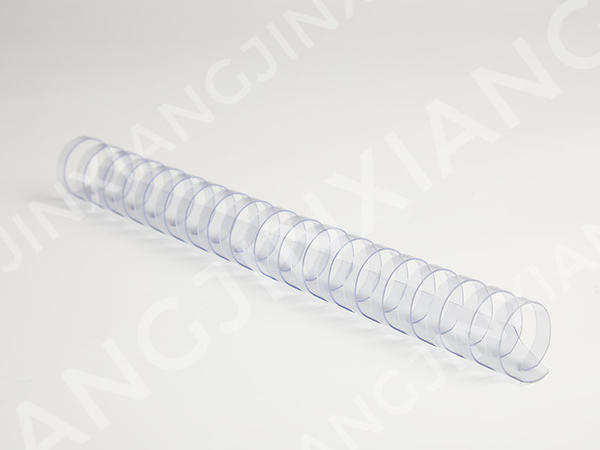

Office Supplies PVC Durable Plastic Comb Binding Rings For Notebook-Plastic Binding Combs/Rings

Office Supplies PVC Durable Plastic Comb Binding Rings For Notebook-Plastic Binding Combs/Rings

English

English 中文简体

中文简体 Español

Español