Ensuring accurate punching and binding alignment is crucial for achieving a professional finish when using double loop wire binding machines. Here are the steps and tips to ensure accuracy:

1.Machine Calibration:

Regular calibration of the double loop wire binding machine is imperative. Follow the manufacturer's guidelines precisely to align the punching and binding mechanisms accurately. This step establishes the foundational accuracy for all subsequent processes.

2.Use Guides and Adjustments:

Utilize the adjustable side guides and depth margin controls meticulously. Accurately setting these parameters ensures that the punching is precise and consistent, maintaining uniformity across the document.

3.Proper Paper Handling:

Implement meticulous paper handling techniques. Before inserting the paper stack, ensure it is squared and aligned. Utilize joggers or tapping surfaces to eliminate any irregularities. Proper handling significantly contributes to the alignment accuracy.

4.Check Punching Pins:

Regularly inspect the punching pins for any signs of damage or bending. Damaged pins can severely affect alignment. Immediate replacement of faulty pins is necessary to maintain the integrity of the punching process.

5.Batch Processing:

Divide large projects into manageable batches. Processing documents in smaller quantities reduces the likelihood of misalignment in extensive paper stacks, ensuring consistent and accurate results.

6.Quality Paper:

Select high-quality paper that is neither curled nor warped. The integrity of the paper directly impacts the precision of punching. Flat, smooth paper stock is essential for achieving accurate alignment during the punching process.

7.Proper Punching Technique:

Train operators to apply even and consistent pressure when operating the punching mechanism. Smooth, controlled motions prevent misalignment during the punch, ensuring uniform holes in every document.

8.Regular Maintenance:

Adhere to a strict maintenance schedule outlined in the user manual. Regular cleaning and lubrication of moving parts are essential. Well-maintained machines operate smoothly, reducing the risk of misalignment due to mechanical issues.

9.Double-Check Margins:

Verify the margin settings meticulously. Accurate margins are critical, as they dictate the distance between the holes and the paper's edge. Proper margin settings guarantee stability in the final bound document.

10.Precision Closing:

Exercise precision during the wire closing process. Ensure that the double loop wires align perfectly with the punched holes. The use of a specialized wire closer tool is recommended to achieve a secure closure without damaging the wires' shape or alignment.

11.Quality Control:

Implement a rigorous quality control process. After binding a sample document, conduct a thorough inspection. Check for hole alignment, wire closure integrity, and overall document appearance. Address any discrepancies promptly to maintain consistent quality standards across all documents.

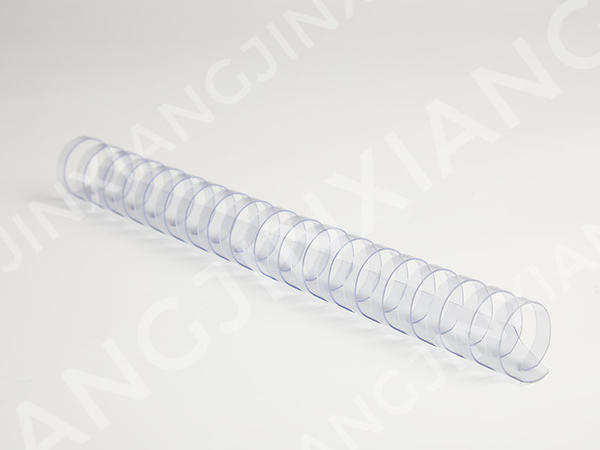

COLOR: BLACK/ WHITE/ COLORFUL/ GOLD/ SILVER/ BRONZE

PACKING: STATIONERY BOX / SPOOL PACKING

English

English 中文简体

中文简体 Español

Español