The disassembly of Multi-Color Single Loop Plastic Coil bindings for document revisions or updates can vary depending on the specific binding system used. Generally, Multi-Color Single Loop Plastic Coil bindings are designed to allow for easy disassembly and reassembly without damaging the document or the coil itself.

Users can typically follow these steps to disassemble and rebind a document with Multi-Color Single Loop Plastic Coil:

Cutting or Trimming: Select a coil cutter with adjustable depth settings, allowing for precise control over the cut depth. This feature is especially beneficial when dealing with varying document thicknesses.

Before making the cut, inspect the coil for any irregularities or deformities. If present, address these issues before cutting to ensure a smooth and clean cut.

Consider using a cutting guide or template to maintain consistency across multiple documents. This helps achieve a professional and uniform appearance in the final result.

Removing the Coil: When unwinding the coil, pay attention to any resistance or tension points. Address these areas delicately to avoid any damage to the coil or the document.

If the document is exceptionally long, consider using a coil unrolling machine for added convenience and to minimize the risk of tangling.

Implement a labeling system for each coil, specifying the document's title or content, making it easier to identify and organize coils during the reassembly process.

Document Edits: Develop a comprehensive revision log, detailing the date, nature of changes, and individuals involved in the editing process. This log serves as an invaluable reference for tracking document evolution.

Collaborate with a diverse group of stakeholders during the editing phase to ensure that all perspectives and requirements are considered.

Leverage version control software or features within document editing tools to track changes systematically, fostering a streamlined and auditable editing process.

Rebinding: When threading the coil, use a coil inserter with adjustable speed settings to maintain precision and control throughout the process.

Periodically check the tension of the coil to avoid overstretching or compression, which could impact the binding's overall integrity.

Incorporate an additional quality control step by conducting a trial closure of the document to identify any potential issues before completing the final crimping.

Crimping or Trimming: Utilize a coil crimper with adjustable settings to accommodate different coil diameters and thicknesses. This ensures optimal crimping performance tailored to the specific binding requirements.

If trimming is necessary, consider employing a precision cutting tool to create perfectly flush coil ends, enhancing the document's professional appearance.

Implement a post-binding inspection process, involving a thorough examination of the entire document to identify any anomalies and guarantee a flawless presentation.

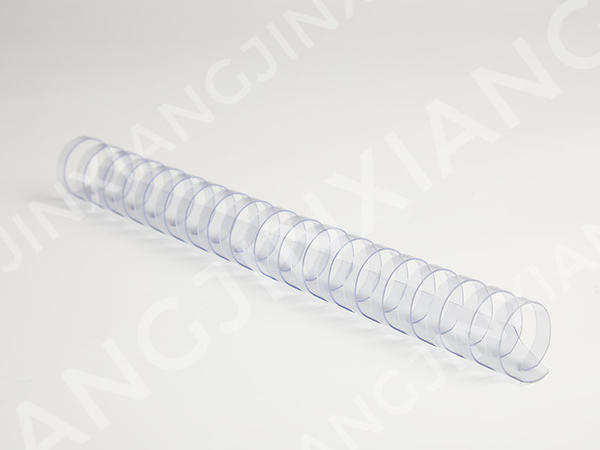

Multi-Color Single Loop Plastic Coil-Plastic Spiral Coil

Multi-Color Single Loop Plastic Coil-Plastic Spiral Coil

English

English 中文简体

中文简体 Español

Español