There are specific safety considerations to keep in mind when using plastic binding combs, especially in high-volume binding operations. Ensuring the safety of personnel and maintaining operational efficiency are crucial. Here are some safety considerations:

1.Machine Safety:

Regularly inspect binding machines to ensure they are in good working condition, with all safety features functioning correctly.

Provide machine-specific training to operators, covering safe operation, emergency shutdown procedures, and maintenance protocols.

Post clear instructions and warning signs near the machines to remind operators of safety precautions.

2.Proper Training:

Training should cover the entire binding process, including loading paper, punching holes, inserting combs, and finishing.

Emphasize the importance of following safety guidelines and the correct sequence of operations to reduce the risk of accidents.

3.Ergonomics:

Ergonomic workstations should include adjustable chairs, work surfaces, and footrests to accommodate employees of varying heights and body types.

Encourage regular breaks and provide anti-fatigue mats to reduce strain from prolonged standing.

4.Eye Protection:

Employees should wear safety glasses or goggles that provide adequate protection against flying debris or particles during hole punching or comb insertion.

5.Hand Protection:

Gloves with appropriate cut-resistant properties should be provided and worn when handling plastic combs or performing tasks where hand protection is necessary.

6.Ventilation:

Install effective ventilation systems to remove dust or fumes generated during the binding process.

Ensure that employees have access to personal protective equipment (PPE) like masks if needed.

7.Emergency Procedures:

Establish a clear protocol for shutting down machines and evacuating the area in case of emergencies.

Conduct regular emergency drills to ensure that all employees are familiar with the procedures.

8.First Aid:

Maintain well-stocked first-aid kits in easily accessible locations throughout the workspace.

Train employees in basic first-aid procedures and designate trained personnel as first-aid responders.

9.Fire Safety:

Install fire extinguishers, fire blankets, and smoke detectors in the workspace.

Conduct fire drills to ensure that employees know how to respond in case of a fire emergency.

10.Material Handling:

Train employees on proper lifting techniques, emphasizing the use of legs and not the back when moving heavy loads of plastic combs or paper.

Provide equipment like hand trucks, carts, or forklifts for transporting heavy materials.

11.Quality Control:

Implement quality checks at various stages of the binding process to identify and correct errors promptly.

A well-organized quality control process reduces the need for rework and minimizes potential accidents caused by document binding issues.

12.Safety Signage:

Use clear and easily understandable signs to mark areas with potential hazards, such as "Caution: Hot Surface" near heat-sealing equipment.

13.Regular Inspections:

Conduct routine safety inspections of equipment and work areas to identify and address potential hazards.

Document inspection results and ensure that identified issues are resolved promptly.

14.Reporting:

Establish an open and anonymous reporting system for employees to communicate safety concerns or incidents.

Encourage employees to report even minor incidents or near misses to identify potential areas for improvement.

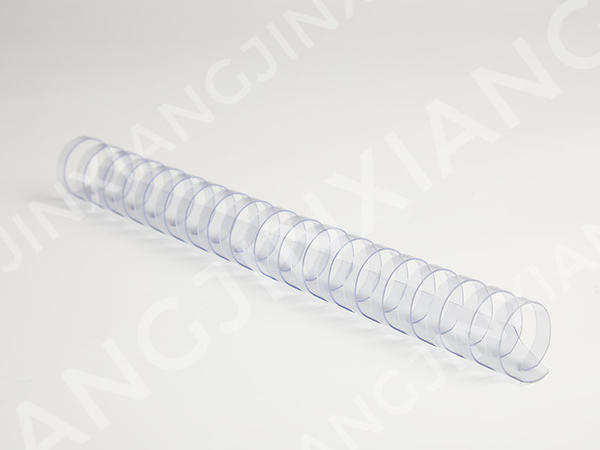

COLOR:Black/White/Red/Yellow/Blue/Green/Clear/Gray/Maroon/Navy blue

Normal 21rings, also can order specific rings, such as 19/38/84rings.

PACKING: White box/ Corrugated box/ Color box.

SIZE:According to Binding's diameter, it could divide into19 species.

English

English 中文简体

中文简体 Español

Español